| Based on our paradigm of Solar Robotics, the Robotic Tracking System (RTS) fundamentally re-invents the design of all solar tracking systems. |

| Conventional tracking systems use metal and concrete materials in sub-optimal fashion. The result is massive and expensive systems that are failure prone and difficult to install. Typically, the material content of all tracking systems is two to three times higher than fixed-tilt systems.

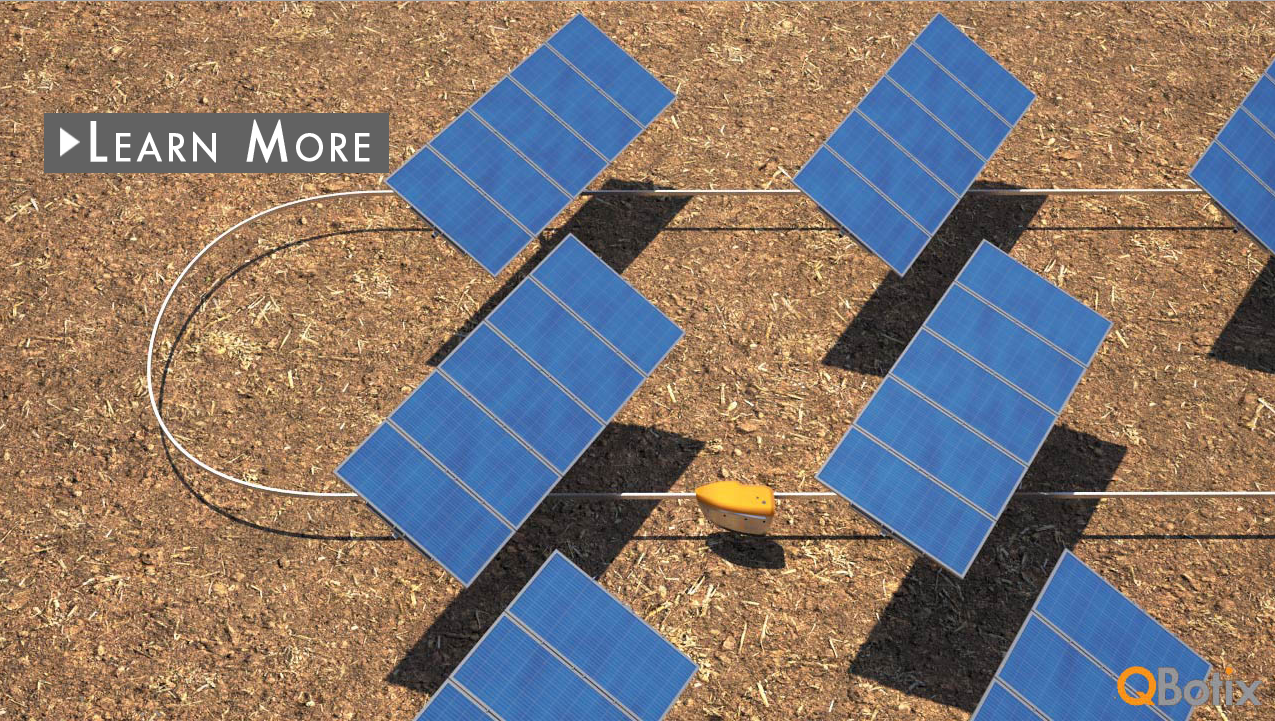

The fundamental reason for sub-optimal material utilization is due to the desire to have each actuation and control system track many panels that collectively comprise a large surface area. The alternative is having motors and control systems for many small trackers, which results in significant actuation costs and low reliability. We approach the problem with a completely fresh approach. We began by designing a tracking system that was optimized in terms of material utilization and that would provide the strength, robustness and reliability needed over the 20 plus year life of the solar project. Then we solved the underlying system-level actuation and controls requirement through our paradigm of Solar Robotics™. The RTS employs a pair of autonomous, mobile robots to control up to 378 kW of solar modules with high accuracy, reliability, and 100% redundancy. The solar modules are installed on the QBotix designed trackers without individual motors and are optimized for cost, strength, durability, and installation simplicity. The robots travel on a rail and adjust each tracker periodically to optimally face the sun. |

| This allows us to create a tracker optimized for material usage, reliability, ease of installation, and maximized production.Each rugged robot replaces hundreds of individual motors and controllers found on conventional tracking systems. In addition, the use of two robots per block or loop provides built in system redundancy. This improves the system reliability and ensures high availability of tracking capability.

The embedded intelligence and data communication capabilities of each autonomous robot enable both optimized power plant performance and detailed operational knowledge at an unprecedented level. |

|

|

|

| Solbot Autonomous, rugged and mobile. Each robot can operate and monitor a 378 kW PV array. |

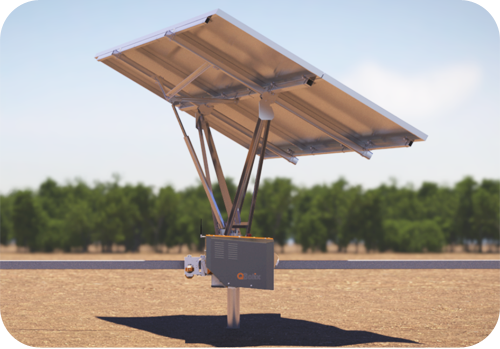

Tracker The trackers are pre-assembled, reliable, easy to install and universally compatible with all modules. |

Robotic Tracking System The Robotic Tracking System (RTS) is an optimized, dual-axis tracking system that maximizes energy production everywhere. |